-

Home

- About Us

- Product Center

- Case

- News

Product CenterSichuang Glass FiberClassify

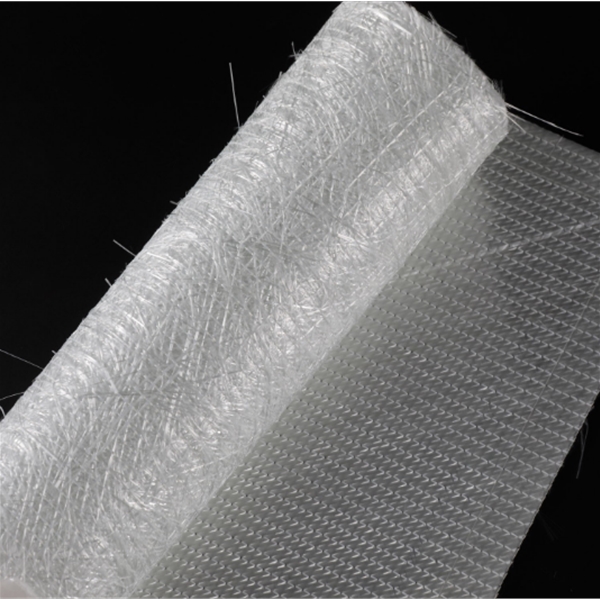

Product CenterSichuang Glass FiberClassifyFiberglass double biaxial fabric +45/-45 °

- Type:E-GLASS FABRICS

- Code:

-

E-glass stitch chopped strand mats are a fabric by chopping continous strands into chopped strands of certain length and stitching together the chopped strands.

- Product Description

Fiberglass double biaxial fabric is made of fiberglass direct roving parallel aligned in +45°and -45°directions, then stitched together with or without chopped strand layer as combo mat. It is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, wind energy, automotive, sports equipment, containers etc, suitable Vacuum infusion, hand lay-up, pultrusion, RTM forming processes. Product List Serial No. Product No. Area Weight (%)ISO3374 Moisture Content (%)ISO3344 Combustible Content (%)ISO1887 Width (mm) ISO5025 1 EWK300 -5.0/+10.0 ≤0.20 6.9±1.4 ±3 2 EWK380 -5.0/+10.0 ≤0.20 5.4±1.1 ±3 3 EWK450 -5.0/+10.0 ≤0.20 4.9±0.9 ±3 Product Features Mat width ranging from 100mm to 600mm No binder is used and polyester thread is used for selvedge binding Good strand dispersion and uniform area weight Good moldability and easy roll-out Good wet-out in resins,resulting in high molding productivity Package: Each stitch chopped strand mat is wounded onto a paper tube which has an inside diameter of 73mm,and the roll has a diameter of 260mm.The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper.The rolls are to be horizontally placed.For transporation the rolls can be loaded into a container directly or on pallets. Storage: Unless otherwise specified,fiberglass products should be stored in a dry,cool and rain-proof area.It is recommended that the room temperature and humidity should be always maintained at 15℃-35℃ and 35%-65%respectively.

{1}

{2}

{3}

{4}

{5}

{6}{7}{8}{9}{10}

{11}{12}{13}

{14}

{15}{16}{17}{18}{19}

{20}{21}{22}

{23}

{24}

{25}

{26}

{27}

{28}

{29}

{30}

{31}

{32}

{33}

{34}

{35}

{36}

{37}

{38}

{39}

{40}

{41}

{42}

{43}

{44}

{45}

{46}{47}

{48}{49}

{50}-

About Us

Company ProfileEnvironmentHonor -

Product Center

E-GLASS Chopped Strands E-GLASS FABRICS Chopped Strand Mat E-Glass Fiberglass Rovings -

News

Corporate News Industry News -

Contact Us

Mobile phone:+8615865924444 Contact: Manager Shi Telephone:0534-7766818 Email:sichuangcomposites@gmail.com Address: Pingyuan County, Dezhou City, Shandong Province Contact Us

Copyright ©2025 Dezhou Sichuang Fiberglass Co., Ltd. All rights reservedTechnical Support:JISU - About Us